Dalian Insulator Group Co., Ltd. mainly produces porcelain insulators and composite insulators, and its manufacturing history of porcelain insulators has lasted more than one hundred years. Having experienced technical reform and technical innovation, currently, the Company has relatively advanced domestic technological equipment, including an 80-meter tunnel kiln, three 180-cubic meter drawer kilns, a 130-cubic meter drawer kiln, 2 automatic forming lines, 2 automatic assembly lines, 9 low air-circulation dryers, 9 5-ton ball grinding mills and 2 electric inspection lines, the low air-circulation dryers of which are first used among the same domestic industries.

In 1984 year we had cooperation with QINGHUA University and developed composite insulator, we improvement them nearly 30 years, our company invest two hundred million to built a 60000 square composite insulator production base and bought many advanced production and testing equipments. Now there are many technological equipments, for example vacuum kneading machines, pressure kneading machine, injection machine, open silicone rubber back-mixed machine, precision pre-former, rubber filter, flat vulcanization machine, crimping machine, assemble umbrella machine, ultrasonic cleaning equipment, material testing machine and so on.

Horizontal vacuum pug mill of Germany SAMA

Electrotechnical porcelain CNC cylindrical profiling machine of Germany SAMA

Bending strength tester of Germany SAMA

Casing CNC fettling machine

15 tons ball mill

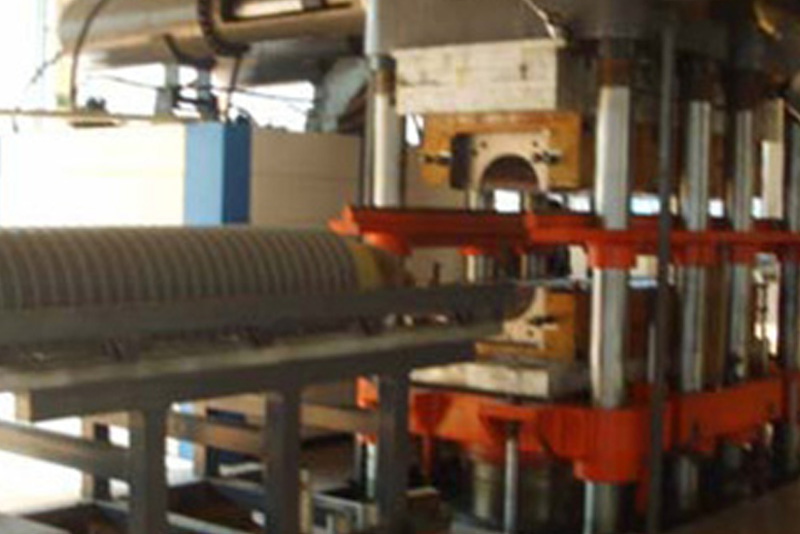

Automatic forming production line

Vacuum pug mill

80m high speed nozzle tunnel kiln

Bending resistance test

Injection molded machinery